Preventing Hose Failures: A Materials Selection Guide

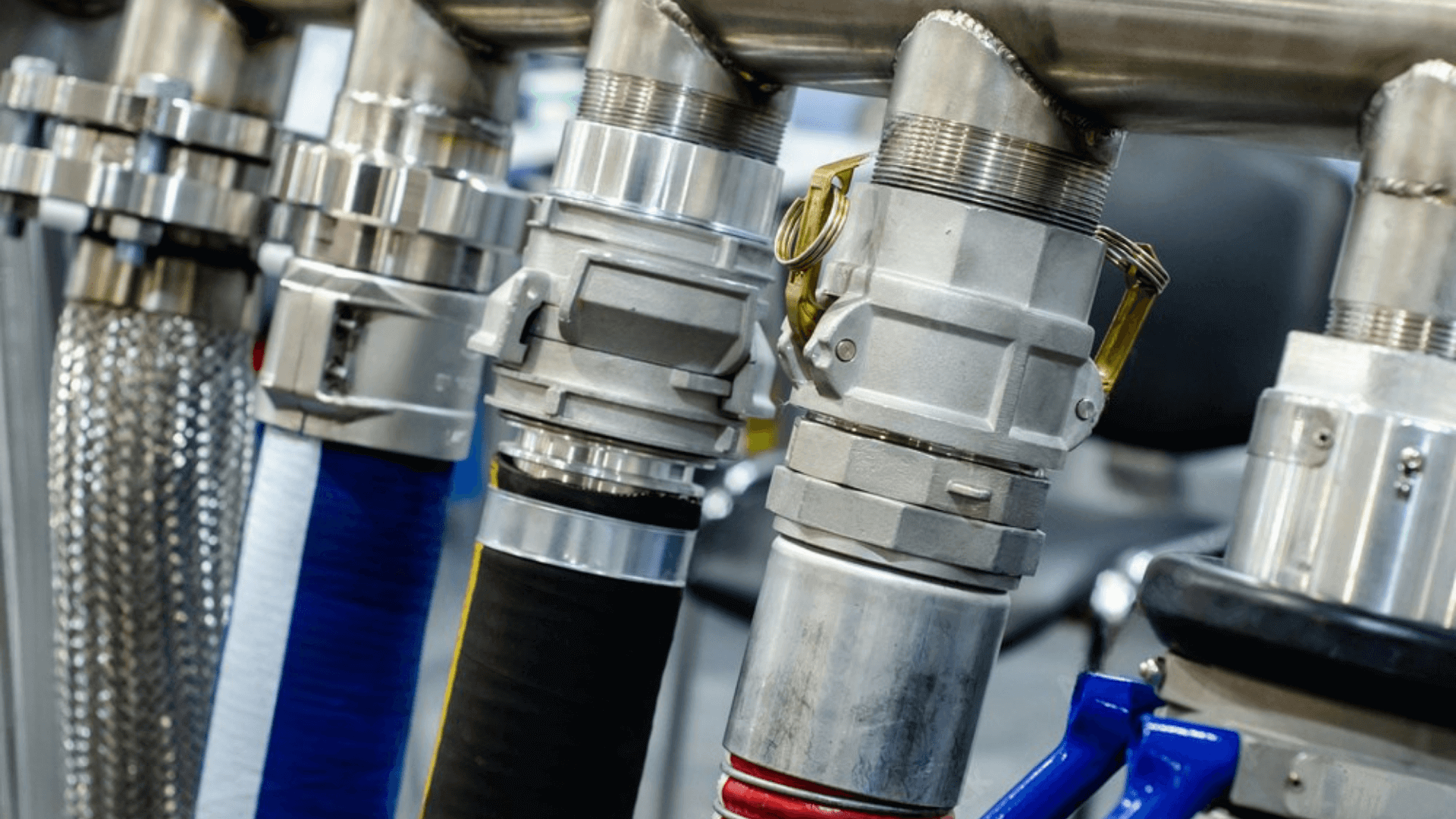

When it comes to industrial hose applications, selecting the appropriate material isn’t just about performance, it’s about safety, efficiency, and avoiding costly downtime. The wrong choice can lead to premature failures, chemical incompatibility issues, and even dangerous situations. Understanding the properties, compatibility, and applications of different hose materials is essential for workers across any industry.

Key Hose Materials and Their Properties

Buna Nitrile Rubber (NBR)

Buna Nitrile Rubber stands as one of the most versatile synthetic rubbers in industrial applications. Its excellent resistance to petroleum-based oils, fuels, and many chemicals, make it a go-to choice for oil and gas operations. NBR exhibits good abrasion resistance and maintains flexibility across a moderate temperature range (-40°F to 225°F), however, it shows poor resistance to ozone, weathering, high temperatures, and ketones making NBR hoses more suitable for applications where there is adequate protection from the environment and UV exposure.

Best Applications: Automotive fuel lines, hydraulic systems, oil transfer hoses, and general petroleum product handling.

SBR (Styrene Butadiene Rubber)

SBR represents an economical general-purpose synthetic rubber that offers good abrasion resistance and flexibility for basic industrial applications. It performs well with water, air, and mild aqueous solutions, making it suitable for many standard uses, however, SBR shows poor resistance to petroleum products, oils, and fuels, limiting its use in hydrocarbon environments. Operating effectively from -65°F to 180°F, SBR provides a cost-effective solution where chemical resistance is not the primary concern.

Best Applications: Water transfer, compressed air lines, general material handling, and applications where cost-effectiveness is prioritized over chemical resistance.

EPDM (Ethylene Propylene Diene Monomer)

EPDM rubber offers exceptional resistance to heat, ozone, and weathering, making it the ideal choice for outdoor applications and agricultural services. It performs well with polar chemicals, mild acids, and alkalis, but shows poor compatibility with petroleum products and oils. EPDM can handle temperatures from -65°F to 300°F and maintains excellent flexibility at low temperatures making it a popular choice for HVAC systems, marine environments, and industrial settings.

Best Applications: Construction applications such as water or chemical transfer, hot water systems, chemical processing (non-petroleum), and exterior installations requiring weather environmental durability.

Silicone Rubber

Silicone rubber excels in extreme temperature applications, maintaining flexibility across an exceptionally wide temperature range from -100°F to 400°F. It offers FDA compliance for food applications and excellent biocompatibility for medical uses, however, while silicone provides superior temperature stability and flexibility, it exhibits poor abrasion resistance and limited chemical compatibility with many solvents and fuels, making it unsuitable for heavy-duty or chemically aggressive environments.

Best Applications: Food and beverage processing, medical applications, high-temperature steam service, and specialized applications requiring extreme temperature flexibility.

PVC (Polyvinyl Chloride)

PVC hoses provide excellent resistance to acids, alkalis, and salt solutions at an economical price point, making them popular for basic chemical handling applications and favourable in pulp & paper facilities. This material offers good clarity for visual monitoring of fluid flow and maintains reasonable flexibility at moderate temperatures. However, PVC becomes rigid in cold conditions and shows poor resistance to organic solvents and hydrocarbons, operating most effectively from -10°F to 150°F.

Best Applications: Agricultural irrigation, water transfer, mild chemical handling, pool and spa applications, and general-purpose fluid transfer where cost is a primary consideration.

UHMPE (Ultra-High Molecular Weight Polyethylene)

UHMPE represents the pinnacle of chemical resistance among thermoplastic materials. This material offers outstanding protection to a broad range of corrosive substances, including strong caustic acids, bases, alkalis, and organic solvents. Its low coefficient of friction and excellent abrasion resistance make it ideal for demanding applications and is popular in pulp & paper and chemical processing facilities. Additionally, UHMWPE hoses meet FDA standards, ensuring safe handling of beer, wine, soft drinks, fruit juices, and other food products. UHMWPE operates most effectively from -200°F to 180°F.

Best Applications: Chemical transfer lines, slurry handling, food and beverage transfer, and applications requiring extreme chemical resistance.

XLPE (Cross-Linked Polyethylene)

Cross-linking technology transforms standard polyethylene into a high-performance material with enhanced temperature capabilities and improved chemical compatibility. XLPE maintains the chemical resistance of polyethylene while offering better performance at elevated temperatures and improved stress-crack resistance, operating effectively from -100°F to 200°F. However, this enhanced performance comes with increased weight compared to its UHMWPE counterpart.

Best Applications: High-temperature chemical processing, bulk storage transfer, and applications requiring both chemical resistance and structural integrity.

The Critical Importance of Chemical Compatibility

Chemical incompatibility between hose materials and process fluids can result in catastrophic consequences that extend far beyond simple equipment failures, and understanding these risks is essential for safe operations.

Immediate Hazards of Incompatibility

Hose Degradation and Failure: Incompatible chemical and hose pairings can cause both rapid deterioration of hose materials through swelling, hardening, or chemical attack, leading to sudden ruptures and immediate safety hazards. However, chemical incompatibility can also result in gradual deterioration that often goes unnoticed during routine inspections, ultimately leading to catastrophic failure or unexpected leaks with significant environmental and safety consequences.

Chemical Contamination: Incompatible materials may leach compounds into process fluids, contaminating products and potentially creating health hazards that can become particularly critical in food-grade applications and chemical processing operations where product purity is essential for safety and quality standards.

Fire and Explosion Risks: Degraded hose materials may lose their structural integrity and ability to safely contain flammable materials, while chemical reactions between incompatible substances can generate dangerous heat buildup or produce volatile byproducts that significantly increase fire and explosion hazards.

Making the Right Choice: A Systematic Approach

Selecting the optimal hose material requires a systematic evaluation of multiple factors:

Chemical Compatibility: Always consult detailed chemical compatibility charts and consider not only the primary chemical being transferred, but also any additives, impurities, and cleaning agents that may come into contact with the hose throughout its operational lifecycle.

Temperature Requirements: Consider both operating and ambient temperatures, including potential temperature spikes during startup or unusual operating conditions, as excessive heat can cause hoses to become brittle and develop fractures, while cold temperatures can similarly result in brittleness and structural failures that compromise hose integrity.

Pressure and Vacuum Conditions: Ensure the selected hose material can handle both positive pressure and potential vacuum conditions without collapse or failure, while verifying that adequate reinforcement is incorporated to withstand the full range of pressure differentials and vacuum scenarios encountered during operation.

Abrasion and Wear Considerations: Evaluate whether the application involves abrasive materials or frequent flexing that might accelerate wear, as transferring abrasive substances like slurry, gravels, sand, sawdust, and similar materials can rapidly deteriorate hoses not specifically designed for abrasive applications. Additionally, hoses that are flexed beyond their specified bend radius can experience structural collapse, stress fractures, weak points, and pin holes that compromise system integrity.

Environmental Factors: Consider UV exposure, which can cause material degradation and cracking over time, along with ozone levels, temperature fluctuations, humidity, salt air exposure, and other weathering factors that can accelerate aging and compromise material performance, particularly in outdoor installations where hoses face continuous environmental stress.

Regulatory Requirements: Various industries impose specific material requirements, restrictions, and compliance standards that must be thoroughly evaluated and incorporated into the hose selection process, such as FDA approval for food and beverage applications, USP Class VI certification for pharmaceutical use, API standards for oil and gas operations, and Coast Guard approval for marine environments.

Conclusion: Investing in the Right Choice

The selection of appropriate hose materials is a critical decision that impacts safety, efficiency, and operational costs. While the initial cost difference between materials may seem significant, the long-term value of proper material selection far outweighs the upfront investment, as choosing the cheapest option often proves to be the most expensive when factoring in replacement expenses, downtime, and potential safety incidents.

Working with experienced hose manufacturers and suppliers like Corestock Industrial Supply who understand both material properties and application requirements is essential. It’s important to remember that the material characteristics outlined above represent general properties of base materials, and actual hose performance and safety ratings depend significantly on manufacturing processes, reinforcement, cover materials, and end fitting configurations. Considerations such as wall thickness, braided reinforcement, spiral wire reinforcement, and specialized cover compounds can dramatically alter a hose’s pressure rating, temperature range, and chemical compatibility.

When in doubt, conduct compatibility testing or pilot programs to validate material performance before full-scale implementation, and remember, the most devastating hose failure isn’t the equipment expense itself, it’s the cascading consequences of production stoppages, environmental cleanup, workplace hazards, and lost productivity that make thoughtful hose selection one of the most important decisions in industrial operations.

For assistance with material selection for your specific application, consult with our technical team who can provide detailed compatibility assessments and recommendations based on your unique operating conditions and specific hose construction requirements.